Preserve the Strength and Beauty of Your Floors

One of the most often underestimated nemesis of concrete floors is moisture. Especially for epoxy resin flooring contractors. Concrete is the strongest foundation we know of, and yet, too many contractors neglect to treat moisture trapped in their foundation.

As you'll soon see, concrete moisture is an easy way to introduce more possibilities of system failure in any epoxy resin flooring project. In this article, we explore the significant impact of concrete moisture on surfaces and how to effectively combat it.

Hidden in Plain Sight: Concrete Moisture

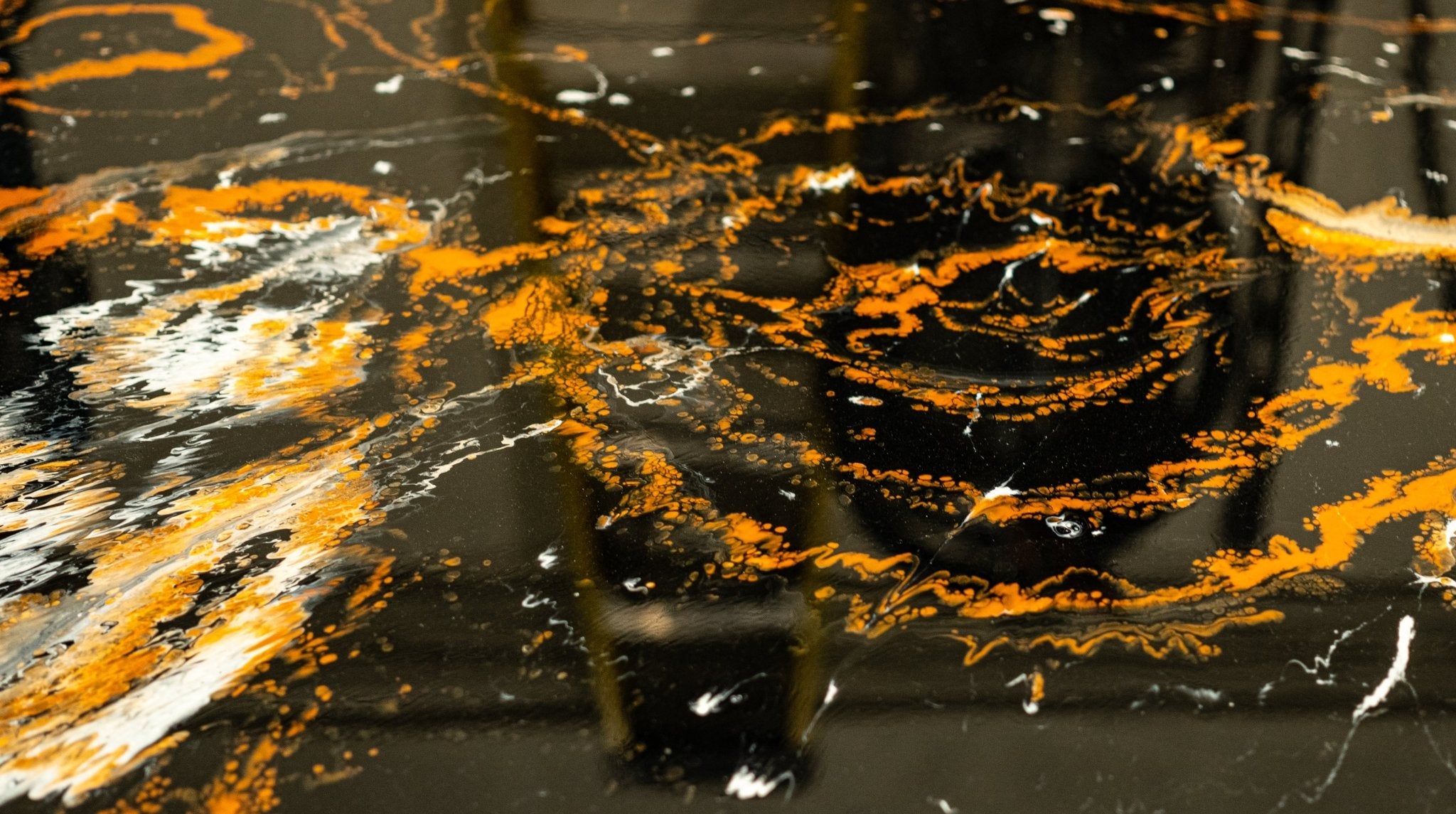

While concrete might seem impervious, it can harbor hidden moisture, akin to a sponge. This hidden moisture can wreak havoc on concrete surfaces, especially epoxy coatings.

This moisture accumulation below the surface can lead to issues like discoloration, cupping, buckling, blistering, adhesive failure, and mold growth, as noted by DeFelsko. The trickiest part is that this threat isn't always visible. It might lie dormant within the concrete, revealing itself only with changes in temperature or over time, emphasizing the importance of testing.

The Root Causes

Understanding the sources of concrete moisture is vital for effective mitigation. Achieving 100% dry concrete is seldom feasible or necessary, as per ConcreteMoisture. But, all too often, contractors are settling for not nearly dry enough concrete! Common sources of moisture include:

1. Freshly Poured Concrete: If you're starting from scratch on a flooring project, it's important to be aware that fresh concrete is a haven for moisture. You have to let it evaporate before you start applying epoxy.

2. Hydrostatic Pressure: If you're working in an area with a high water table, it's possible for water to be pushed up due to hydrostatic pressure.

3. Humidity: In regions with temperate climates, like Florida's humid summers, atmospheric humidity can permeate older concrete over time. Humidity will often lead to surface moisture problems.

The Significance of Concrete Moisture Testing

To solve a problem, you have to know the problem. You can almost never get the full picture of a concrete's moisture level just by observation. That's why we use moisture testing procedures. Moisture testing serves as a diagnostic tool to determine the moisture content within the concrete substrate, and there's a few different ways to test.

Moisture testing tools are especially necessary in humid / temperate climates because even concrete that appears dry can conceal moisture. When the stakes are the success of your flooring project, it's always good to be thorough! Applying coatings without accurate testing often leads to adhesion failure.

Proven Methods of Concrete Moisture Testing

-

Moisture Meters: Moisture meters are the most common way to gauge moisture content within the concrete. There's varieties of meters, as well. Pin-type meters require inserting pins into the concrete at various locations and depths, while non-destructive meters are placed on the concrete surface, following the manufacturer's guidelines. But, even if destructive meters are more accurate, any testing is preferable to none.

-

Relative Humidity Testing: This method involves placing sensors within the concrete to measure relative humidity. It's particularly vital in humid climates. Relative humidity testing is necessarily destructive. You'll need to drill holes into the concrete to insert sensors, which must be left for the manufacturer-specified duration, typically 24-72 hours.

-

Calcium Chloride Testing: This method is less accurate than the others, but it's also incredibly affordable & easy to do. Place a sealed calcium chloride container on the concrete surface. As the container absorbs moisture, the weight gain determines the moisture vapor emission rate (MVER). It'll take a little longer than the other methods, typically around 60-72 hours.

If you have any additional questions about specifics, or which test is right for your jobs, our team of technicians is always around to help!

Effective Solutions for Concrete Moisture

It's not hard to keep your floors safe for years to come! It just takes a couple extra steps, some careful thought and thorough planning.

Your best defense will always be a moisture barrier solution. Moisture barrier and vapor-reducing products, such as XPS's high-quality line, act as protective shields, hindering moisture from advancing to the surface.

As with most other epoxy resin flooring issues, proper surface preparation, achieved through methods like shot blasting or diamond grinding, is your first line of defense! Surface preparation should create a clean, dry & just porous enough concrete surface profile that will get you that strong bond you need. If moisture levels are within an acceptable range, the moisture barrier can be omitted, but it's never wrong to be too safe.

Conclusion

Every contractor will need to understand the sources of moisture, be able to conduct thorough testing, and implement effective mitigation strategies to stay at the top of the industry! At XPS, we empower contractors with the tools to master these techniques. Choose knowledge, choose preparedness, and choose XPS to help you craft concrete & epoxy floors that withstand the test of time.

Are you a contractor & need help on the job? A DIY enthusiast looking for your next renovation? Xtreme Polishing Systems (XPS) online store is the headquarters of all things concrete & epoxy flooring! If you need it, we got it. Reach out to our team for any additional assistance you might need.