Why Install Epoxy Flake Floors?

Epoxy flake floors have rapidly become one of the most popular systems across both residential and commercial markets. Contractors prefer them because they are reliable, scalable, profitable, and forgiving during installation. DIY users love them because they look great, hide imperfections, and dramatically upgrade their garage or shop without a full renovation.

Here are the main reasons people choose epoxy flake flooring:

1. Industrial-Grade Durability

A properly installed epoxy flake flooring system is built to withstand heavy foot traffic, tools, machinery, forklifts, and vehicle tires. The combination of an epoxy base and a polyaspartic or urethane topcoat creates a hard, resilient surface that resists chips, spills, abrasion, and wear.

2. Slip-Resistant and Safer

Epoxy floor chips add natural traction to the floor, reducing the risk of slips in both wet and dry conditions. This makes it a top choice for gyms, auto shops, commercial kitchens, and garages.

3. Chemically Resistant

Epoxy flake floors stand up to oil, gasoline, chemicals, cleaning solutions, brake fluid, salt, and other contaminants. This makes cleanup fast and prevents long-term floor damage.

4. Hides Imperfections

Because flakes provide full broadcast coverage, they naturally conceal cracks, patchwork, and small flaws in the concrete slab. This is a major benefit for older garages and high-traffic commercial spaces.

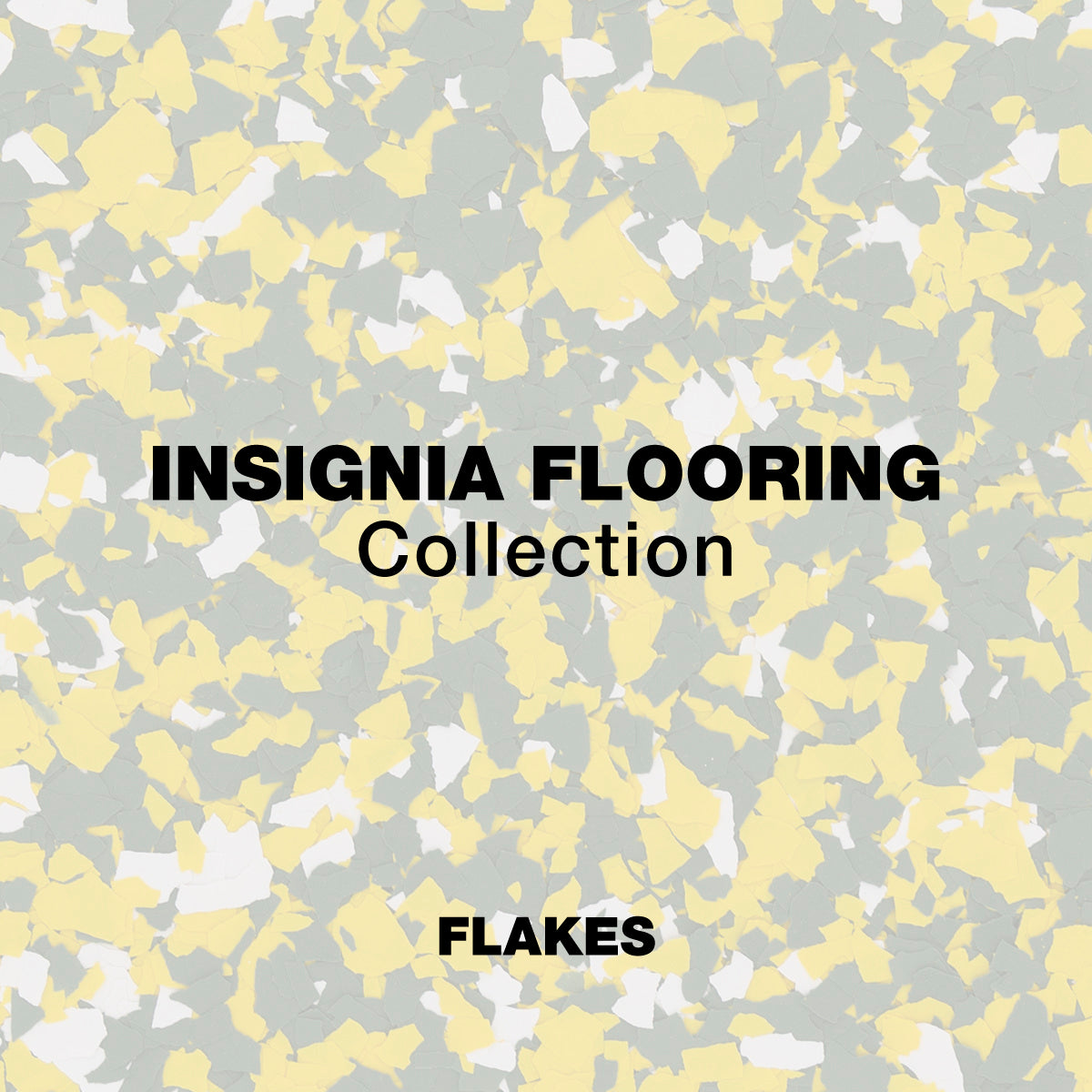

5. Completely Customizable

With endless color blends, flake sizes, and finish styles, you can match any design preference—from a clean and simple garage floor to a showroom-quality finish.

6. Fast Installation Options

Choose between: 1-Day Polyaspartic Flake System or 2-Day Epoxy + Polyaspartic System

Contractors prefer the 1-day system, while homeowners often choose epoxy-based systems due to the ease of working time.

Where Epoxy Flake Flooring Is Used

Epoxy flake flooring is suitable for both home and commercial surfaces.

Residential Uses

- Garage floors

- Basements

- Laundry rooms

- Workshops

- Home gyms

- Utility rooms

- Patio or porch areas

Commercial & Industrial Uses

- Automotive shops

- Retail stores & showrooms

- Commercial warehouses

- Gyms and fitness centers

- Manufacturing facilities

- Schools and universities

- Airplane hangars

- Clinics and health care offices

- Car dealerships

- Storage spaces

If it has concrete, epoxy flake floors can improve it dramatically.

How Epoxy Flake Flooring Works

Choosing the Right System: 1-Day vs. 2-Day vs. Full Epoxy

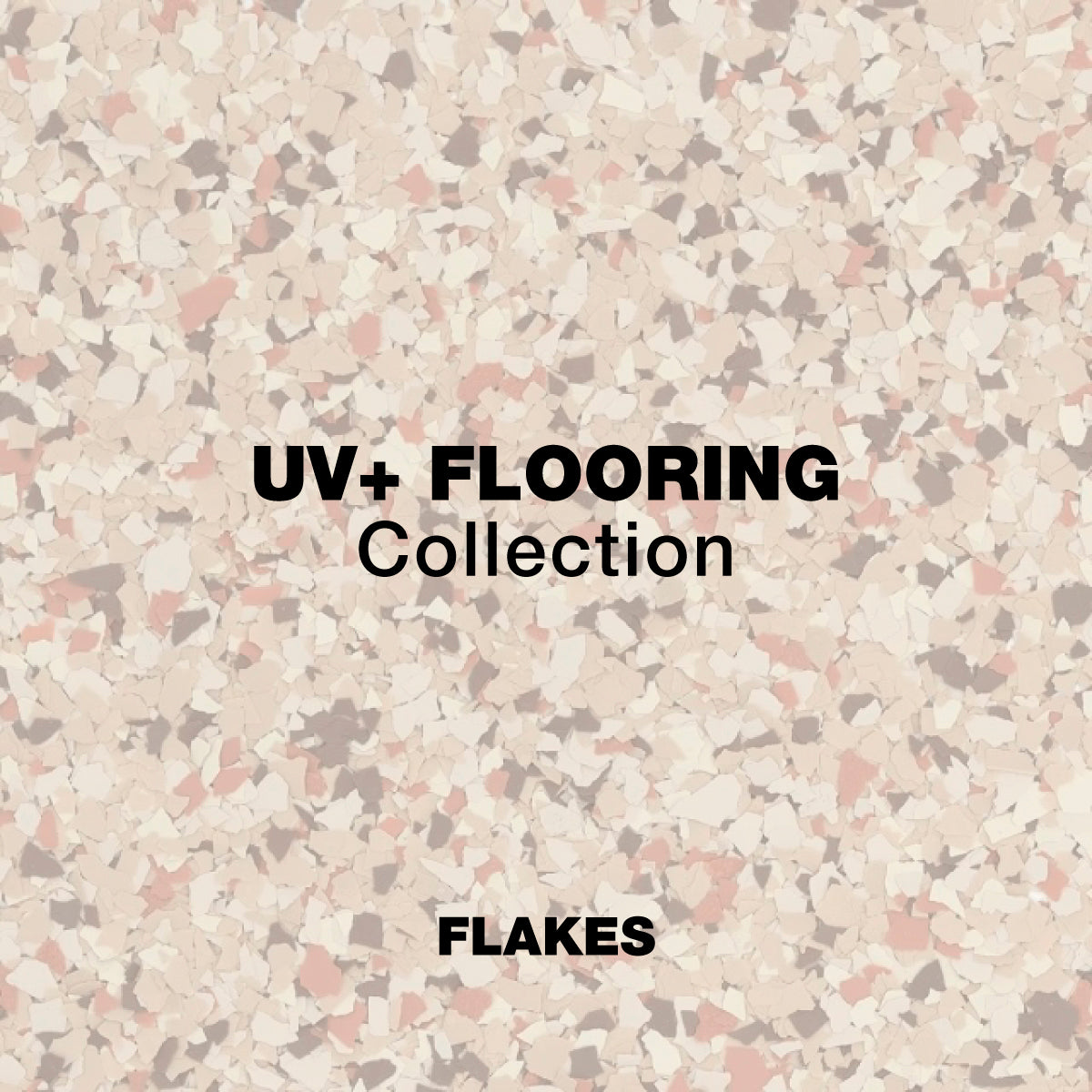

1-Day Polyaspartic Flake System

- Fast cure time

- Perfect for contractors

- High abrasion resistance

- Cold-temperature friendly

- Strong UV resistance

Ideal for:

- Commercial spaces

- Garages with quick turnaround

- High-traffic environments

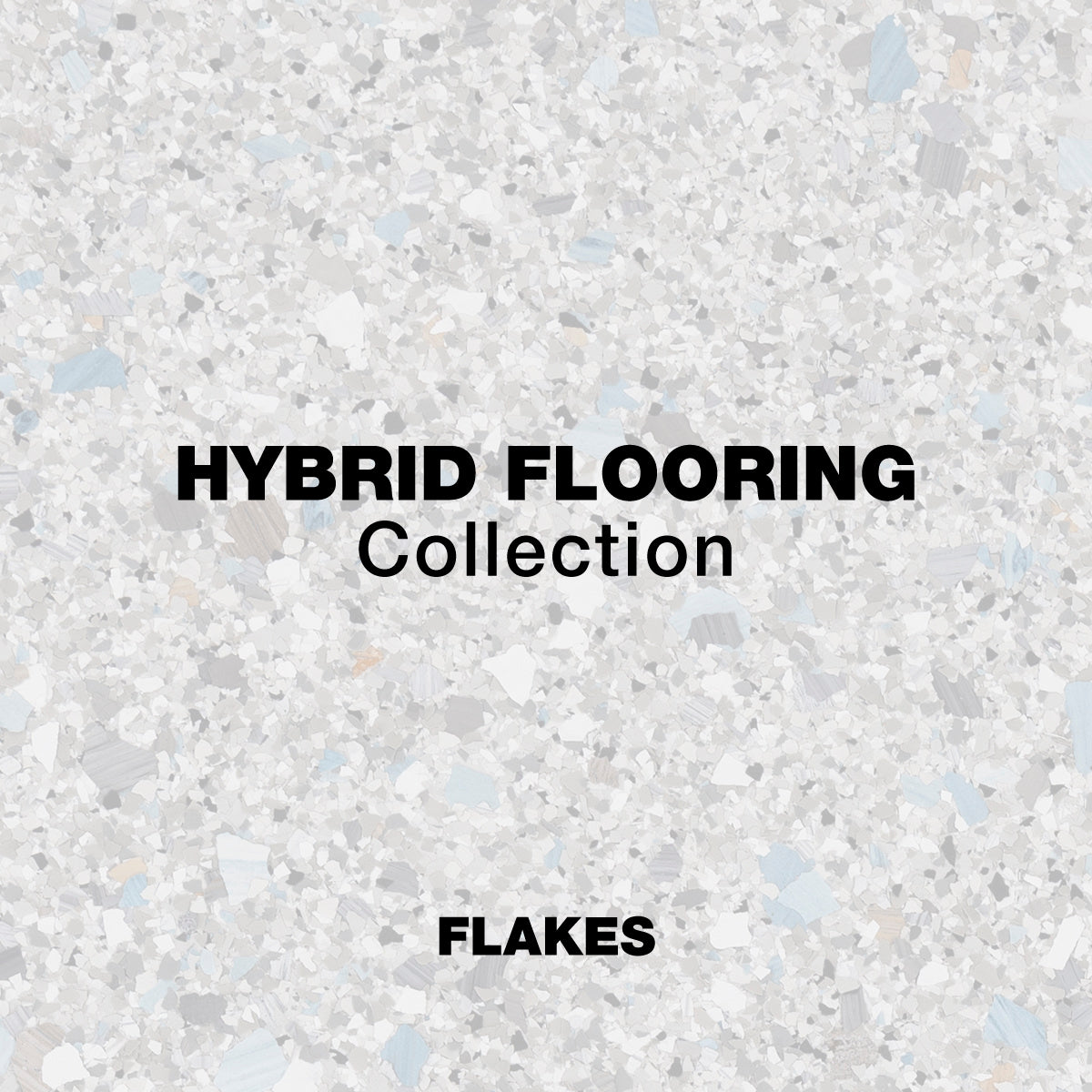

2-Day Epoxy + Polyaspartic System

- More working time

- Easier for DIY users

- Strong adhesion and finish

- Extremely durable

Ideal for:

- Residential projects

- Larger spaces require working time

- Beginners

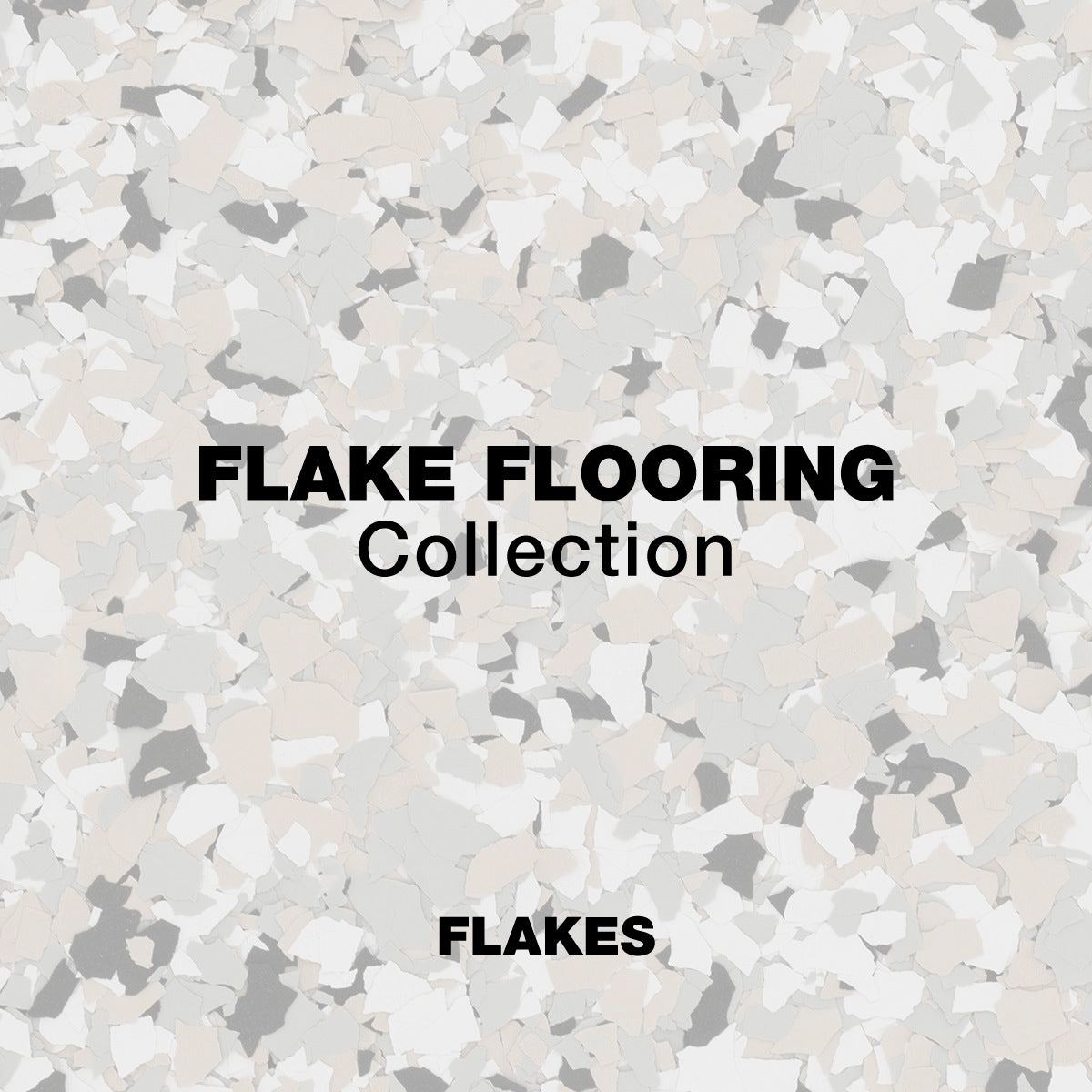

What Are Epoxy Floor Chips?

Epoxy floor chips (also called decorative flakes or vinyl color flakes) are small chips made of vinyl or acrylic that are broadcast into wet epoxy or polyaspartic coatings. They provide:

- Color

- Texture

- Slip-resistance

- Depth and style

- A natural stone-like finish

Flake size options typically include:

- 1/16” (fine texture)

- 1/8” (most popular)

- 1/4” (more texture)

We offer hundreds of blends, including grey mixes, earth tones, high-contrast blends, blue tones, and custom colors.

Benefits of Epoxy Floor Chips in High-Traffic Areas

Epoxy floor chips offer several advantages for both commercial buyers and DIY users:

- Increased traction

- Customizable aesthetics

- Reduced visible dirt

- Conceal small cracks

- Added thickness

- Superior wear resistance

- Long-term color stability

This makes them ideal for environments where safety and durability matter.

FAQ

The amount you need depends on how heavy you want the coverage. A full broadcast typically requires 12 to 20 pounds of flakes per 100 square feet. A medium broadcast usually needs 5 to 8 pounds per 100 square feet. A light broadcast can use as little as 1 to 2 pounds per 100 square feet. Quartz is slightly heavier, so expect to use more material to achieve full coverage.

The most common size is 1/4 inch because it provides balanced texture and a clean look. Contractors often choose 1/8 inch when they want a finer, more uniform appearance. The best size depends on the look you want and how much texture you prefer on the surface.

Yes. Decorative flakes and quartz can be used with almost any epoxy or polyaspartic coating system. They bond to the base coat while it is still wet and become part of the floor once the topcoat is applied. Always make sure the coating has enough working time to broadcast the material evenly before it begins to set.

Yes. Both flakes and quartz increase traction and improve slip resistance. Quartz offers a more aggressive texture and is often used in commercial or industrial environments. Flakes provide a smoother but still safe surface that works well for garages, gyms, and general-purpose areas.

Decorative flakes are vinyl chips that add color and style to the floor. They help hide imperfections and give the surface a clean and modern appearance. Quartz is a much harder and more textured material made from natural sand that has been color-coated. Quartz systems are used when maximum durability and traction are required. Both options enhance the floor, but quartz delivers a more industrial level of performance.

A full broadcast completely covers the base coat. This provides the best hide, durability, and overall appearance. Partial broadcasts use less material and leave some of the base color visible. Full broadcast is recommended for garages, commercial spaces, gyms, and high-traffic areas. Partial broadcast works for decorative or budget-focused projects.

Yes. Many DIY users successfully install epoxy flake floors as long as they follow proper surface preparation and application steps. Flakes are easy to broadcast and help hide small imperfections in the concrete. Quartz is also DIY friendly but requires more material and a thicker coating system to hold it properly. Beginners often start with flakes because they are more forgiving.

Flakes are UV stable and maintain their color well. Quartz is also UV stable because it is made from mineral sand that is color-coated for stability. The topcoat you choose is what determines overall UV protection. Polyaspartic topcoats offer the best UV resistance for both flakes and quartz.

A properly installed flake or quartz floor can last 10 to 20 years or longer. Longevity depends on surface preparation, the quality of the coating system, and how much traffic the floor receives. A polyaspartic topcoat will usually extend the lifespan of the system and improve long-term durability.

Flakes work well in garages, basements, gyms, retail stores, offices, showrooms, and residential areas. Quartz is ideal for commercial kitchens, warehouses, manufacturing spaces, auto shops, food and beverage facilities, restrooms, and any environment that needs maximum traction and durability. Both options improve the appearance, performance, and safety of concrete floors.

To complete your project successfully, you will need:

- Floor grinder

- Diamond grinding tooling

- HEPA vacuum

- Squeegees

- Rollers

- Mixing buckets

- Spike shoes

- Crack repair materials

- Moisture meters

We offer all recommended tools and accessories, including contractor-grade floor machines for large installations.

Our best-selling flake colors include:

- Domino (black, white, grey)

- Orbit (greys with blue tones)

- Shoreline (coastal tan/grey mix)

- Stonehenge (stone-like blend)

- Creek Bed (earth tones)

- Wombat (warm/neutral greys)

We also offer metallic/flake hybrid effects and custom colors.

Epoxy flake floors are low-maintenance and easy to clean. To extend their lifespan:

- Sweep regularly

- Use a mop with pH-neutral cleaner

- Avoid harsh abrasives

- Recoat when the surface begins to wear

Avoid dragging metal tools