For the longest time, clients and contractors alike have had to choose between two directions for their floors: aesthetics, or strength. With epoxy resin though, that is no longer a sacrifice you need to make! We could go on for hours about the aesthetic versatility of epoxy resin flooring systems, but what makes it so strong? Resin has been trusted to support floors ranging from small residential garages, to the largest of industrial warehouses. So, what's its secret?

Our team at Xtreme Polishing Systems has put together a guide on all the strength measurements you need to know to decide if epoxy resin is the best option for your floors!

What Does Strength Actually Measure?

Compressive Strength:

This indicates the resistance epoxy has to being crushed or compressed under heavy loads. Typically measured in PSI (pounds per square inch), compressive strength shows how well the epoxy withstands pressure. If you don't want your floors to begin sinking or having their adhesion impacted by incredibly heavy loads, you'll need compressive strength.

High-performance epoxies are known to hold up to 15,000 PSI or more, making them ideal for environments with heavy machinery or constant traffic. Even commercial resin solutions contain the necessary compressive resistance your garage or commercial project may need.

Tensile Strength:

Tensile strength refers to how much pulling force the epoxy can endure before it breaks apart. This is also measured in PSI and plays a significant role in determining how well the epoxy resists cracking when subjected to pulling forces. Strong tensile performance means the epoxy is less likely to fail in high-stress conditions, such as shifting floors or dynamic loads.

Depending on your location, it's unlikely you'll need to deal with tensile strength much. But, in those odd situations where you will need it, you'll surely not regret having it.

Flexural Strength:

Flexural strength gauges how much bending or flexing the epoxy can tolerate without cracking or breaking. In commercial settings, high flexural strength ensures that the epoxy remains durable even when subjected to heavy or uneven loads. It's particularly useful in areas where the floor might experience constant mechanical motion.

For example, industrial warehouse floors are often facing high-load forklifts carrying pallets of heavy materials across them constantly throughout a work day. A floor with a high flexural strength resists the damages that would impact most other flooring solutions.

Peel Strength:

Peel strength measures how strongly the epoxy bonds to the substrate, commonly concrete. This bond is crucial for long-lasting installations. Peel strength is often influenced by surface preparation—rougher surfaces provide a better grip, while smoother ones could result in premature delamination.

While peel strength is most significantly affected by surface preparation, improper mixing & curing as well as material choice are not insignificant factors.

Maximizing Epoxy Strength for Your Flooring Project

Maximizing the performance of your epoxy floor begins with meticulous preparation and the right choice of materials:

-

Perfecting Your Surface Preparation:

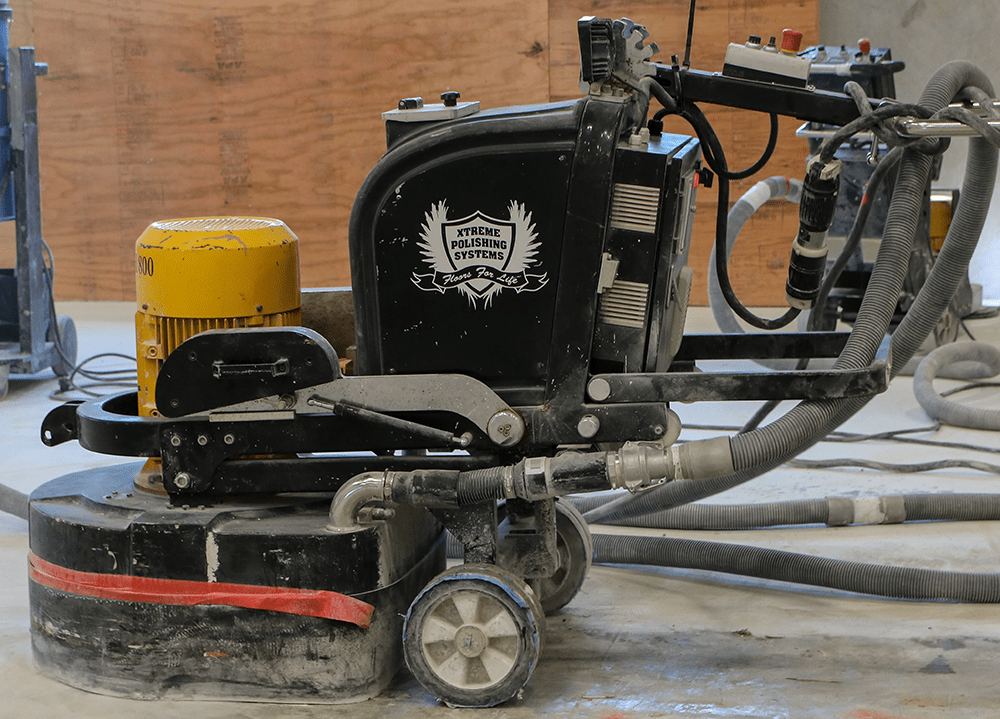

One of the most critical factors in maximizing epoxy strength is proper surface preparation. Diamond grinding or shot blasting creates the texture necessary for optimal adhesion, and ensuring that the concrete is free of dust, debris, or contaminants will help enhance the epoxy's bond. -

Climate Control (Humidity, Moisture, Temperature & More):

Both humidity and temperature play significant roles in how well epoxy cures. Consistent temperatures ensure a uniform cure, while excessive moisture can weaken the adhesive properties. If your environment is prone to high humidity, consider using moisture-tolerant primers. -

Choose the Right Epoxy Resin System:

Not all epoxies are created equal. High-strength epoxy resins are formulated to resist both compressive and tensile forces, but some variants offer higher flexibility or resistance to chemicals and UV light. Consult with professionals to match your epoxy type with the specific needs of your project. -

Test for Performance, Test for Failures:

Measuring moisture content in the concrete and testing adhesion strength before full application will help prevent issues such as peeling or bubbling. Epoxy testing kits can provide precise data to ensure that your floor will meet the required performance standards.

Conclusion

Before committing to an epoxy flooring project, familiarize yourself with the essential strength measurements—compressive, tensile, flexural, and peel strength. Even though it stands a head above the competition when it comes to strength, your project might need even more protection. Knowing what you're looking for is step one to realizing your vision. Nail the right subfloor preparation, purchase the right epoxy system for your project, and attain ideal installation conditions and we promise you'll optimize the performance and durability of your floor!

Xtreme Polishing Systems (XPS) is your central hub for all things concrete & epoxy flooring! Our veteran technicians are on-call at (877) 958-5264 for any assistance with approaching a project, or buying the right resources. And don't forget our online store is the best place to find the materials you need at prices you want!