In this article, we reflect on the different advantages and disadvantages surrounding each finish and also discuss the unique traits that contrast both refinished concrete floors and resurfaced concrete floors. This is to ensure that you know exactly how to maintain each one accordingly before moving forward, whether it is a job, renovation, or personal project.

Introduction: Concrete is Everlasting

Every day people are losing interest in outdated procedures and old-fashioned methods used for purposes surrounding foundation and structure. For example, the flooring industry used to be dominated by veterans such as wood and tile yet are now steering toward more sustainable and reliable choices for hard flooring surfaces. New industry demands initially started this trend shift to utilize other natural materials that were just as able to create hard surfaces, like concrete and natural stone flooring. Natural stone includes materials such as granite, marble, and porcelain however, concrete has always been considered the most predominant of the choices. This is a direct result of the material itself requiring much less attention and maintenance when compared to natural stone flooring, which requires a considerable amount of care and attention. In addition, the general cost of concrete flooring is more economical in contrast to natural stone, and most importantly it is the most resilient of the many flooring choices.

Concrete is truly an innovative building material that is optimum for achieving the most specific needs for construction and structural-related industries. Over the years, people took notice of the versatility of concrete leading to its truest form of innovation and growth in the global industry altogether. With endless possibilities for design and structure, modern-day concrete surfaces have a vast range of options that typically include flooring, counters, and bar tops. In fact, there are plenty of builders, contractors, and do-it-yourselfers that have further expanded their innovation by utilizing the material for other everyday surfaces. Recent trends for concrete furniture and also concrete walls (BEFORE vertical installation) have truly expanded the use of concrete, setting the bar higher every passing day.

Sustainable, beautiful, and reliable foundations are universal desires throughout ALL sectors of the industry. Due to this, it has increased industry demand drastically for achieving the most satisfying concrete floor finishes that deliver strength, sustainability, and produce very satisfying appearances. The use of concrete surface applications will shield them against continuous wear and tear, exposure to harmful contaminants, and other common damages it may endure over time. The question then begins to shift from “should concrete floor surfaces be protected” to “what are the best options for protecting my concrete floor surfaces?” Today’s assortment of concrete floor finishes and their unique differences could easily cause anyone to become overwhelmed, frustrated, or even feeling defeated. The act of continuous browsing can be very extensive with the selection of concrete finishes, decorative styles, and surface designs that are available in the market today. Nonetheless, there is no need to worry. Xtreme Polishing Systems has been dedicated to the industry for concrete flooring and is here to assist our customers simply because they are our #1 priority.

Concrete renovation is occasionally referred to as concrete restoration or concrete maintenance. These are familiar terms used in the industry are simply just a broad representation of the general use of concrete surface treatments or material-based concrete surface applications used for rehabilitating, restoring, and protecting concrete floor surfaces. However, concrete restoration is much more complex in its representation once broken down. The different concrete techniques, surface methods, and finish designs used in the field by real, hard-working industry professionals can help give a better understanding of the true meaning behind the meaning of concrete renovation. To better assist our readers and provide them with the most up-to-date and accurate trade knowledge, we narrowed down the term and divided it into two very distinct categories: concrete refinishing and concrete resurfacing.

Concrete Refinishing aka Polished Concrete

Concrete refinishing is all about changing the color or restoring the surface in exposed concrete floors as found in some homes and businesses, particularly those in tropical and semi-tropical areas. This comprehensive concrete floor solution is typically applied to corporate offices, residential garages, and many other flooring projects as they possess great versatility and are extremely cost-effective.

Concrete refinishing is not only a durable flooring solution but also aesthetically satisfying as it can highlight a colored and high-gloss finish. Moreover, polished concrete is also low-maintenance, and environment-friendly. Refinished concrete floors are not laborious and time-consuming. As polished concrete grows more in demand, different options for concrete flooring equipment and surface techniques are developed each year to optimize the working process and conditions.

Types of Concrete Refinishing Methods

Although undergoing a similar process, the variety of finishes for polished concrete can be executed due to different aggregate levels being exposed during the concrete polishing process. This results in different concrete refinishing techniques including decorative concrete and various different styles of polished concrete floor finishes.

Decorative Polished Concrete

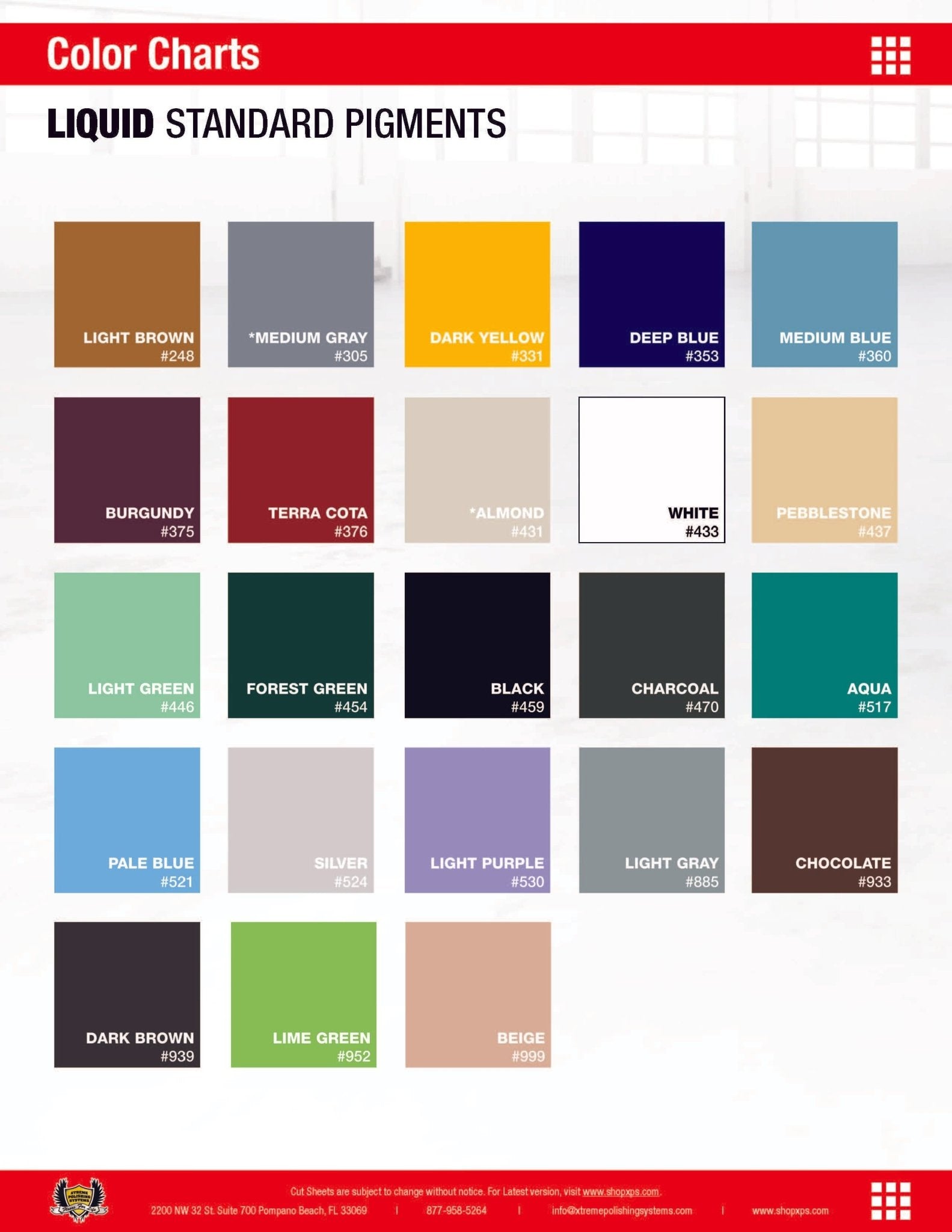

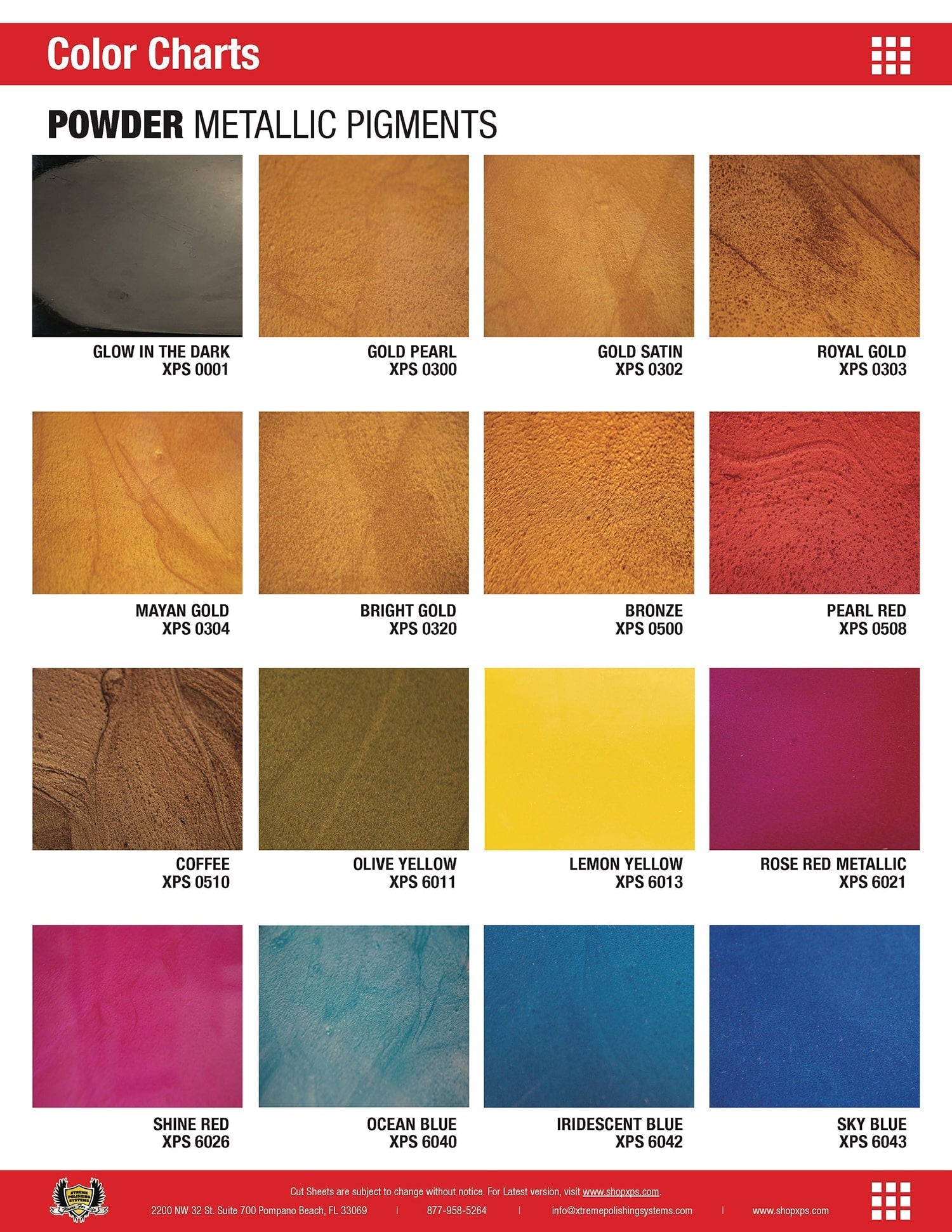

Decorative concrete is also be referred to as architectural concrete because it has received topical surface treatments to create aesthetic enhancements and effects while still serving its function as an integral part of the building itself. Decorative concrete includes coloring concrete, stamped concrete, acid staining, decorative overlays, and other surface beautification methods. Xtreme Polishing Systems provides a diverse collection of concrete dyes and concrete stains that produce earth tones and vibrant colors on concrete surfaces. There are a few important factors to consider when you choose decorative concrete methods like staining or dying your concrete floors; determine the type of concrete you’re coloring, pigment selection, water content, mixing ratio, and unique finishing techniques to help you achieve a beautifully decorated surface. Our supply of concrete dyes and stains enhances the overall look of concrete while complementing the architectural features of the surface.

Bronze Polished Concrete

Bronze polished concrete is also known as the “cream” finish. The top layer gets polished using diamond pads instead of grinding the surface paste back to achieve a creamy gloss. Bronze polished concrete finish acknowledges and preserves the natural texture and color of the concrete slab.

Silver or Full Aggregate Finish

Silver or full aggregate finish produces the most durable polished concrete floor finish. After a series of deep grinding processes, the larger stones in the concrete slab get exposed by grinding the surface paste back 1mm to 3mm deep. Contrary to its namesake, the full aggregate finish is not polished; instead, it sports a matte finish.

Gold or Salt and Pepper Polished Concrete

Gold or salt and pepper finish take advantage of the sands and aggregate under the surface paste to bring out a unique, particular pattern. After exposing the sands and aggregates, the floor then gets polished for a high-gloss finish.

Platinum Polished Concrete Finish

The platinum finish is one of the most popular polished concrete finishes. Like the silver finish, the platinum finish necessitates a series of deep grinding processes to bring out the ballast in the concrete slab. As the desired pattern is exposed, the floor gets polished to a platinum finish that is highly durable and offers a superb aesthetic value as it reflects light off its glossy surface, exuding a majestic glow.

Concrete Resurfacing aka Concrete Coatings

Concrete resurfacing simply put is a process by which concrete is cleaned, repaired, and overlaid with a new surface such as concrete floor coatings, also referred to as floor coverings. Concrete floor coatings are best for both commercial and residential projects because the process of resurfacing concrete creates a durable and nonporous surface finish, leaving your concrete floors protected from mold, filth, or other contaminants. Surface maintenance and sanitation are not nearly as much of an issue, contrary to maintaining wood, tile, and carpet floors since coated concrete floors typically lack the process of repairing and/ or filling concrete joints, cracks, and fissures.

Types of Concrete Floor Coatings

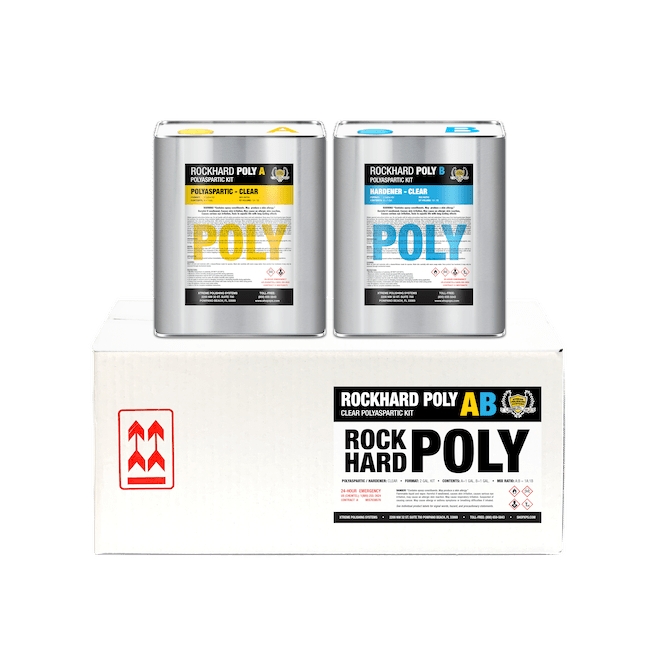

While there is certainly not a shortage of industrial building materials in the market, the four most commonly used concrete coating systems include the most commonly known epoxy floor coatings as well as protective floor coatings which includes polyaspartics, polyurea, and urethane concrete coating systems that produce the most resilient surfaces that will withstand any extreme conditions such as harsh UV conditions which are primarily caused by direct or extreme sun exposure. Furthermore, other options that are familiar for resurfacing concrete include vinyl flake/ chip concrete coating systems, and cementitious toppings including concrete overlays, micro-toppings, and cement-based underlayments. Depending on your project specifications, you may find interest in any of these concrete floor coating systems for your precise concrete resurfacing purposes.

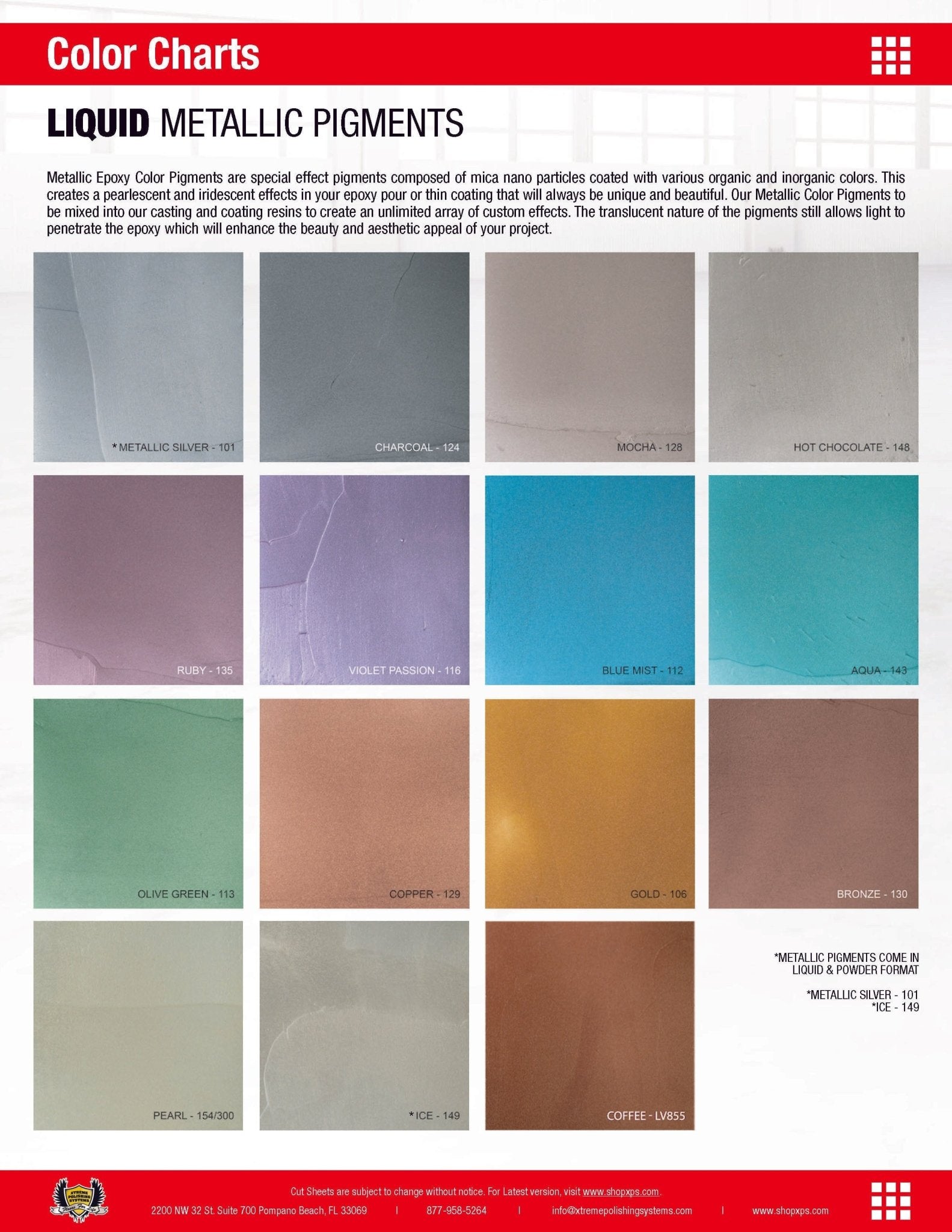

For the sake of comparison, epoxy floor coatings are formulated building materials with very strong adhesive properties helping bond the durable material to the applied surface (concrete flooring, tables, bar tops, etc.). This “sealing” process will thereby create a highly durable barrier that is resistant to water, stain, and mold. In addition, a colorful array of decorative epoxy pigments and color additives, including safety colors, metallics, and dazzling glitter flakes are guaranteed to WOW you, creating a true one-of-a-kind finish that is unique to your specific taste. Comparatively, protective floor coatings like polyaspartic and urethane coating systems are generally paired with vinyl flake/ chips because once combined they can produce UV-stable, non-slip concrete surface finishes able to withstand heavy traffic areas. The utilization of such brilliant materials and durable concrete coating systems can be found in all sectors of the global industry whether it’s residential, commercial, or industrial environments. These settings include garage concrete flooring, industrial warehouses, manufacturing, facilities, and are commonly found in commercial kitchen settings as well.

Concrete Coatings Versus Polished Concrete

Concrete floor coatings involve the application of industrial-grade materials to seal any surface pores and cracks in concrete entirely. These durable floor coverings can yield a pleasantly seamless finish that’s aesthetically stunning in its appearance and also very solid, reliable, and impenetrable to harmful contaminants. Additionally, concrete floor coatings allow users the choice to explore their creative side by providing them the option for decorative color additives to provide artistic assistance with bringing out the desired sheen and to customize the surface overall.

On the other hand, polished concrete requires the removal of any remaining surface treatment or covering so a series of grinding processes can be performed on the surface until the concrete is officially smooth and polished. Concrete floor grinders and floor polishers are used for this particular process because they are built to last and precisely designed to grind, polish, level, smooth, clean, and repair concrete surfaces.

Choosing the Right Flooring Application

Choosing the best flooring application for a certain project involves taking interplaying factors into account, such as the location of the installation, the budget of the project, maintenance plans, the needs and expectations of end-users, among other things.

Sometimes, the decision may end up coming from the existing state and condition of the concrete surface itself. When the concrete surface gets damaged extensively enough that the damage reaches the substrate, polished concrete applications will just not do as the concrete must get repaired or even sometimes replaced entirely. Contrarily, concrete floor coatings may be enough of a solution to conceal minute flaws and imperfections in the concrete surface.

One must also take into consideration future maintenance plans. For one, concrete floor coatings applications may wear off much faster than polished concrete applications, but still may easily be renewed or replaced. Some concrete floor coating systems are designed to only last a few years, which will necessitate a complete replacement. Comparatively, polished concrete floors may require more complex, extensive repairs when seriously damaged. However, polished concrete floors can last several years with very little maintenance so long as there is jus minimal damage caused to the surface.

The bottom line ultimately remains the same for either process: they both reinforce the concrete floor durability, longevity, safety, and visual appeal. The decision, then, boils down depending on interplaying factors such as mentioned above as one technique might be better suited than the other.

Conclusion: A Final Takeaway

SPOILER ALERT: there is no “winner” between the standoff for choosing refinish concrete floors or resurface concrete floors. As established, both methods of concrete floor coatings and polished concrete floor applications will fortify the concrete’s strength, longevity, and aesthetic appeal. The only important factor that needs to be considered is the environment it will be applied to so you choose accordingly. No matter the application one decides on, employing a consistent maintenance routine is necessary to increase the lifespan of a durable, safe, and beautiful concrete floor, whether coated or polished.

This flooring guide provides insight while also helping you acquire the most relevant industry knowledge for overall assurance. It’s our job to instill the necessary confidence for properly choosing the appropriate concrete finishes, based entirely on your specific project needs. Therefore, it doesn’t matter where you currently are in your renovation process, whether it be in pursuit of a career, already existing in the field, or simply just to make personal home improvements, Xtreme Polishing Systems is here to help shine a light on the grey areas that may still be surrounding the different concrete floor finishes.

Xtreme Polishing Systems also wants to ensure that you have the confidence to make these decisions, based on your own preferences. You having a clear understanding of the different specifications maintaining its surface appearance and strength will help people better establish the most reliable concrete surface applications for utmost protection and longevity of your concrete floor finishes. This type of defense for having the proper industry knowledge, professional insight, and essentially your newly developed growth for your personal knowledge bank will give you the certainty needed to have a positive impact and overall well-being of your concrete floor finish.

Conclusion

At Xtreme Polishing Systems, our team of experts understands that concrete can variate in properties, therefore each slab must be treated differently. We also know how common it is for those unforeseen complications to occur after hours while still on the job site. It is crucial to have immediate support for achieving beautiful concrete finishes.

Whether you’re a professional contractor or a do-it-yourself type of person, our top-of-the-line concrete product supply and industry expertise are available to anyone. Our pros are here to discuss all your project concerns to assist you every step of the way, from START to FINISH.

Questions? We would love to hear them! Our professionals are readily available to answer all your questions and to provide you with concrete knowledge and industry expertise in the overall preparation and completion of a concrete floor project. Shop Online or Call (877) 958-5732 for all your concrete flooring needs!